CNC v grooving machine for sheet metal

CNC V grooving machine fully CNC high-speed slotting machine for V-groove machining stainless steel iron plate copper

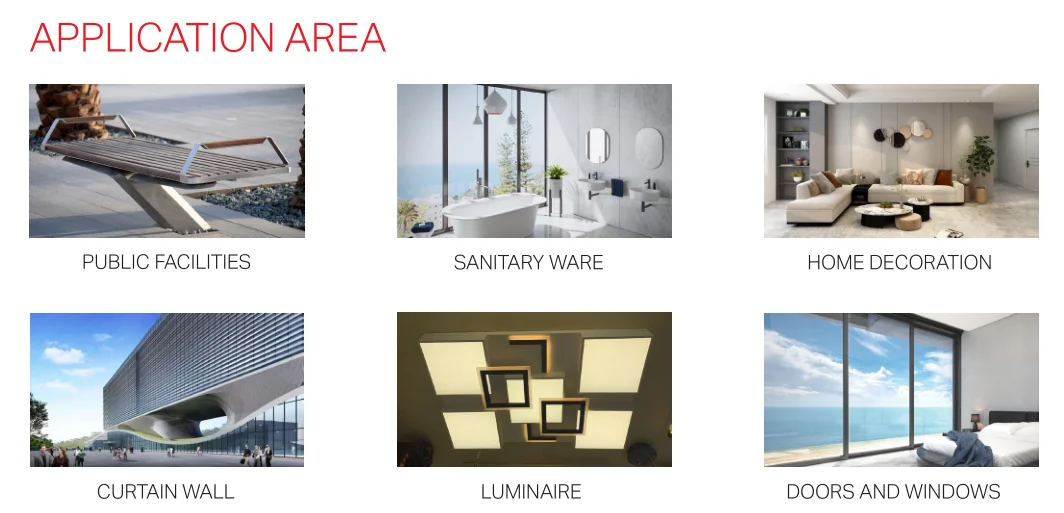

V-groove machining on stainless steel, ordinary iron plate, and copper involves the process of cutting V-shaped grooves into these materials. This technique is commonly used in various industries such as metalworking, manufacturing, and construction for creating precise joints, seams, or decorative features. Stainless steel is chosen for its corrosion resistance and durability, making it suitable for applications in environments where rust or tarnishing is a concern. Ordinary iron plate, often mild steel, is versatile and cost-effective, suitable for structural and general-purpose applications. Copper, known for its excellent electrical conductivity and aesthetics, is used in electrical components, architectural details, and artistic applications. The V-groove machining process typically utilizes specialized machinery equipped with cutting tools designed to achieve accurate depths and angles. This capability allows for the creation of strong and aesthetically pleasing joints or features, ensuring high-quality fabrication across different material types.

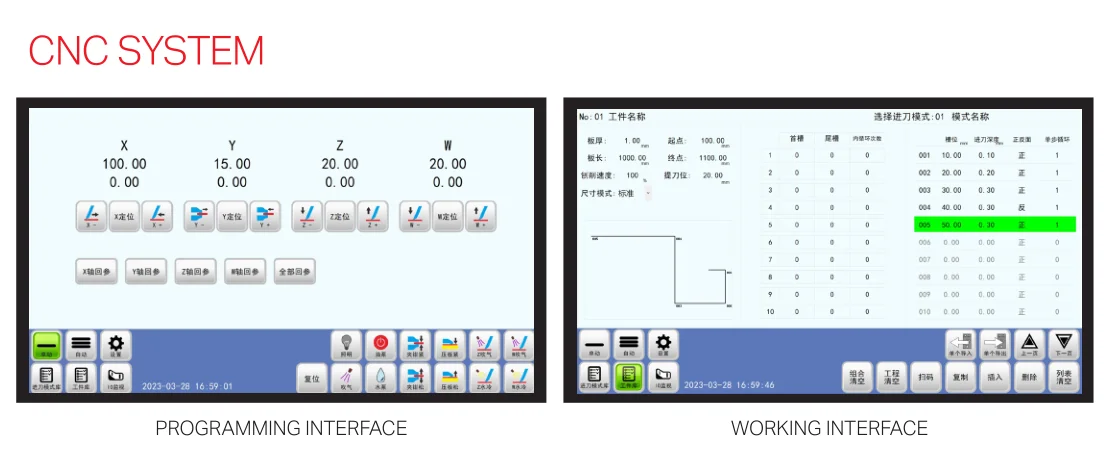

A CNC slotting machine is a specialized device controlled by Computer Numerical Control (CNC) technology, used for slotting operations on metal sheets. This machine automates precise slotting operations and is typically employed in manufacturing components or products requiring precise slot shapes. CNC slotting machines can accurately cut V-shaped, U-shaped, or other specified slots according to programmed instructions. They find wide application in industries such as aerospace, automotive, electronics, and construction, enhancing production efficiency and machining accuracy.

PRODUCT SPECIFICATIONS

Versatile Cutting Capabilities: V-grooving machines can cut V-shaped grooves of different depths and angles, allowing for flexibility in design and fabrication. They can handle various materials, including aluminum, stainless steel, mild steel, and composite materials. CNC Control: Many modern V-grooving machines are equipped with computer numerical control (CNC) systems, which allow for precise and automated control of the cutting process. CNC programming enables operators to specify the dimensions, angles, and patterns of the grooves to be cut. Multiple Cutting Methods: V-grooving machines can employ different cutting methods depending on the material and application. Common techniques include scoring, shearing, milling, and routing. Some machines may also incorporate laser cutting technology for enhanced precision and speed. High Precision: V-grooving machines are capable of achieving high levels of accuracy and repeatability, ensuring consistent results across multiple parts. CNC control and advanced cutting tools contribute to the machine's precision and reliability. Efficiency and Productivity: By automating the cutting process and minimizing material waste, V-grooving machines help improve efficiency and productivity in sheet metal fabrication. They can handle both small-scale production runs and large-scale manufacturing operations with ease. Integration with CAD/CAM Software: V-grooving machines are often compatible with computer-aided design (CAD) and computer-aided manufacturing (CAM) software, allowing for seamless integration of design and manufacturing processes. This enables operators to import CAD drawings directly into the machine's control system for programming and cutting.

|

Model |

NCVM-3200 |

NCVM-4200 |

NCVM-5200 |

NCVM-6200 |

|

|

Manufacturing performance |

Length |

3200mm |

4200mm |

5200mm |

6200mm |

|

Width |

10-1600mm |

10-1600mm |

10-1600mm |

10-1600mm |

|

|

Thickness |

0.5mm-6mm |

0.5mm-6mm |

0.5mm-6mm |

0.5mm-6mm |

|

|

Minimum edge distance |

8mm |

8mm |

8mm |

8mm |

|

|

Manufacturing speed |

Tool holder (axis X) cutting |

0-120m/min |

0-120m/min |

0-120m/min |

0-120m/min |

|

Tool holder (axis X) return |

0-120m/min |

0-120m/min |

0-120m/min |

0-120m/min |

|

|

Feeding (axis Y) |

0-20m/min |

0-20m/min |

0-20m/min |

0-20m/min |

|

|

Tool holder (axis Z) upper and lower |

0-20m/min |

0-20m/min |

0-20m/min |

0-20m/min |

|

|

Manufacturing precision |

Feeding (axis Y) minimum resolution |

±0.01mm |

±0.01mm |

±0.01mm |

±0.01mm |

|

Feeding (axis Y) maximum distance |

1250mm |

1250mm |

1250mm |

1250mm |

|

|

Tool holder upper & lower (axis Z) minimum resolution |

±0.01mm |

±0.01mm |

±0.01mm |

±0.01mm |

|

|

Tool holder upper & lower (axis Z) maximum distance |

30mm |

30mm |

30mm |

30mm |

|

|

Clamping device |

Hydraulic system |

1.5Kw/8L/10Mpa |

1.5Kw/8L/10Mpa |

1.5Kw/8L/10Mpa |

1.5Kw/8L/10Mpa |

|

Outline dimension |

Length |

4250mm |

5800mm |

6380mm |

7550mm |

|

Width |

2700mm |

2700mm |

2700mm |

2700mm |

|

|

Height |

2100mm |

2100mm |

2100mm |

2100mm |

|

|

Weight |

11200kg |

14500kg |

19500kg |

22100kg |

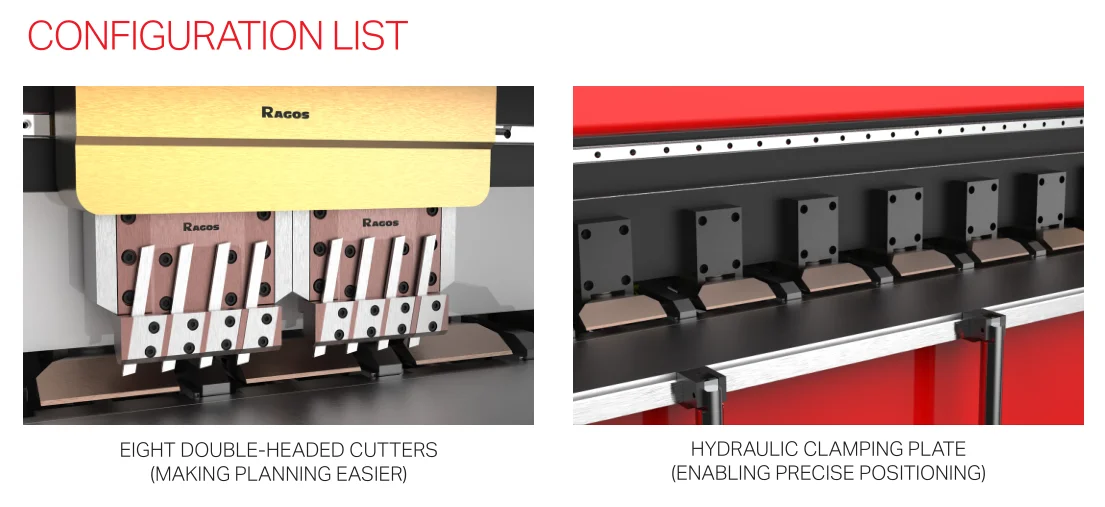

PRODUCT CONFIGURATION