3200MM V Grooving Machine for sheet metal

3200mm V-Groove Machine for Sheet Metal form sharp corners on mild steel aluminum and stainless steel

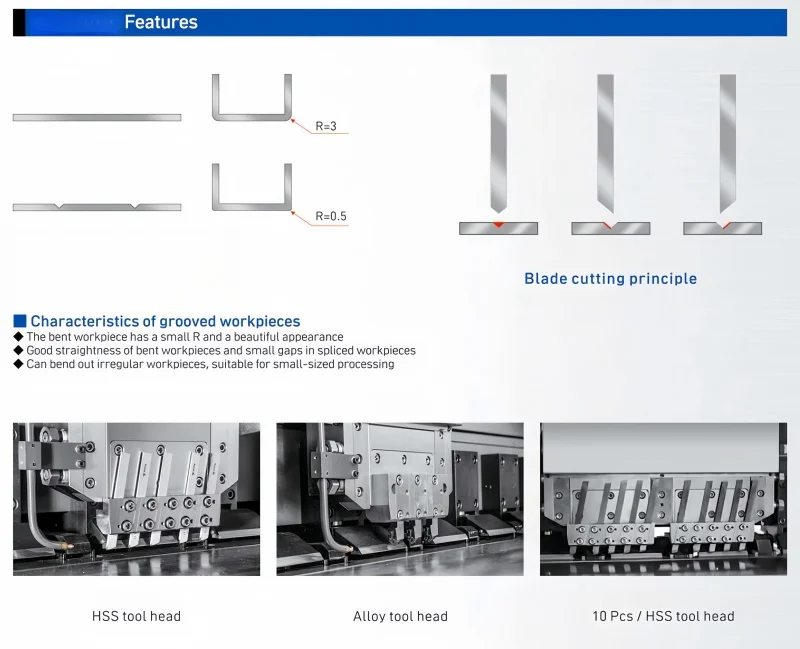

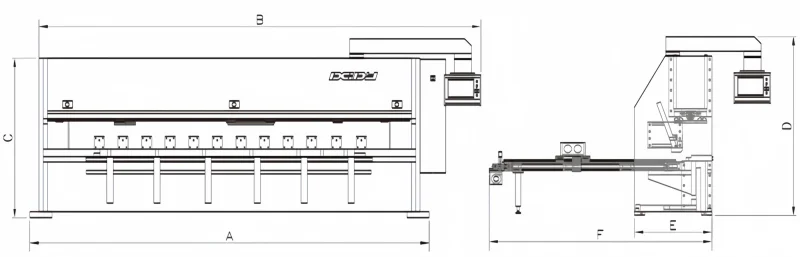

V Grooving Machine for Sheet Metal - DPCK3200 The DPCK3200 V Grooving Machine is a robust, high-performance piece of equipment designed to create precise grooves in sheet metal, enabling the formation of sharp corners on mild steel, aluminum, and stainless steel. This machine is ideal for industrial applications that require accurate bending with clean, crisp edges. Its heavy-duty design and advanced CNC system allow for precise control, making it an essential tool for metal fabrication, architectural panels, and more. Key Specifications - DPCK3200 Model: DPCK3200 Machine Weight: 11,200 Kg Axes: 3-Axis Grooving Length: 3200 mm Material Capability: Mild steel, aluminum, stainless steel Features Precise Grooving for Sharp Bends: The DPCK3200 is designed to create V-shaped grooves in sheet metal, reducing the material thickness at specific points. This allows for the formation of sharp, clean corners or bends, which is particularly useful for architectural metalwork and decorative sheet applications. CNC Control: The 3-axis CNC system ensures precise depth control and positioning of the grooves, resulting in consistent and high-quality results across a wide range of materials. Heavy-Duty Construction: Weighing 11,200 Kg, the machine is built for durability and stability, allowing it to handle large and thick sheets of metal without compromising on precision. Versatile Material Compatibility: The DPCK3200 can process various metals, including mild steel, aluminum, and stainless steel, making it suitable for a wide range of industrial applications. Applications Architectural Panels: Used for creating sharp, clean corners in metal panels, providing a smooth finish for architectural and decorative purposes. Metal Fabrication: Perfect for precise grooving before bending operations, ensuring clean bends in fabricated metal parts. Elevator Panels: Ensures aesthetically pleasing, sharp edges on elevator panels made from stainless steel and other metals. Furniture Manufacturing: Utilized for high-precision grooves in the manufacturing of metal furniture or fixtures.

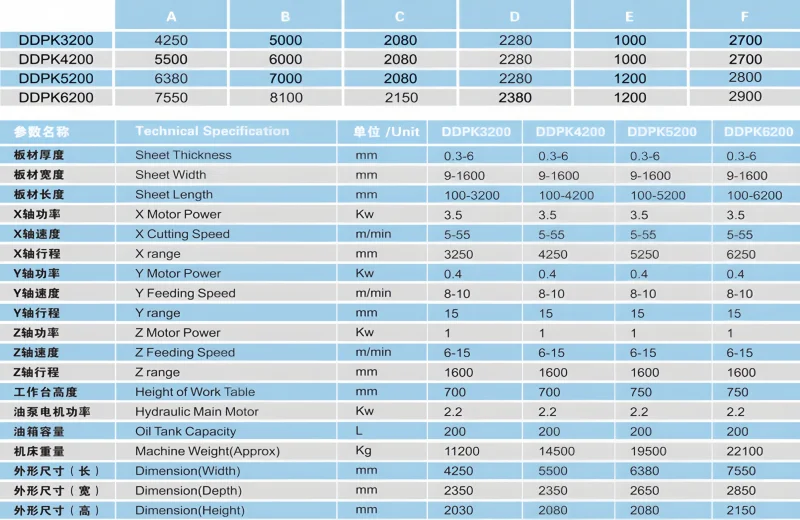

PRODUCT SPECIFICATIONS

|

No |

Item |

Unit |

LC-DPCK3200 |

LC-DPCK4200 |

LC-DPCK5200 |

LC-DPCK6200 |

|

1 |

Plate thickness |

mm |

0.3-6 |

0.3-6 |

0.3-6 |

0.3-6 |

|

2 |

Board width |

mm |

7-1600 |

7-1600 |

7-1600 |

7-1600 |

|

3 |

Processing length |

mm |

3200 |

4200 |

5200 |

6200 |

|

4 |

Workbench height |

mm |

700 |

700 |

700 |

700 |

|

5 |

Oil pump power |

KW |

2.2 |

2.2 |

2.2 |

2.2 |

|

6 |

Fuel tank capacity |

mm |

200 |

200 |

280 |

280 |

|

7 |

Feeding speed |

mm/s |

200 |

200 |

200 |

200 |

|

8 |

Planer speed |

mm/s |

100-900 |

100-900 |

100-900 |

100-900 |

|

9 |

Cutting speed |

mm/s |

280 |

280 |

280 |

280 |

|

10 |

Size |

mm |

5.2*2.3*2.1 |

6*2.3*2.1 |

7.2*2.3*2.15 |

8.1*2.3*2.18 |

|

11 |

Weight |

KG |

11200 |

14500 |

19500 |

22500 |

CNC V-Grooving Machine is specialized equipment used in the sheet metal fabrication industry. Its primary purpose is to create sharp bends by carving a V-shaped groove at the bending line of the workpiece, allowing for a sharper bending angle with a reduced radius, often less than the material thickness. This process results in neat, precise bends, making it ideal for forming clean lines and special shapes. Main Features of the CNC V-Grooving Machine: Sturdy Construction: The machine is fully welded with steel plates, followed by stress-relief treatment, ensuring the machine frame remains deformation-free over time. Imported Industrial Control System: Equipped with an advanced human-machine interface (HMI), the control system provides stable and accurate operation. Precision Drive Components: The machine uses high-precision ball screw and guide rails for transmission, ensuring high accuracy with low noise during operation. Efficient Servo Drive: All positioning units are equipped with imported AC servo drives and motors, ensuring high efficiency and energy savings. High-Quality Hydraulic Components: The hydraulic system features well-known Taiwanese brands, with an interlocking mechanism between hydraulic and transmission parts, ensuring smooth, safe, and reliable operation. Working Principle: The CNC V-Grooving Machine is designed to create a V-shaped groove at the desired bending line of a metal sheet, reducing the material thickness at the bend. This allows the formed part to have a smaller bending radius, resulting in cleaner, sharper bends. It is especially effective for creating uniform and aesthetically pleasing bends, even in complex shapes. Applications: The CNC V-Grooving Machine is widely used in various industries, including: Decorative Panels: Ideal for creating sharp bends in stainless steel for architectural and decorative panels. Machine Tool Enclosures: Used for clean, precise bends in sheet metal parts for machine tool casings and enclosures. Furniture and Display Stands: Employed in the fabrication of metal furniture, display cases, and exhibition stands. Cabinetry and Bathroom Fixtures: Used in the production of cabinets, bathroom fixtures, door panels, and door frames.

PRODUCT CONFIGURATION