6200MM V Grooving Machine for sheet metal

Best 6200M V Grooving Machine for Sheet Metal of stainless steel aluminum and mild steel

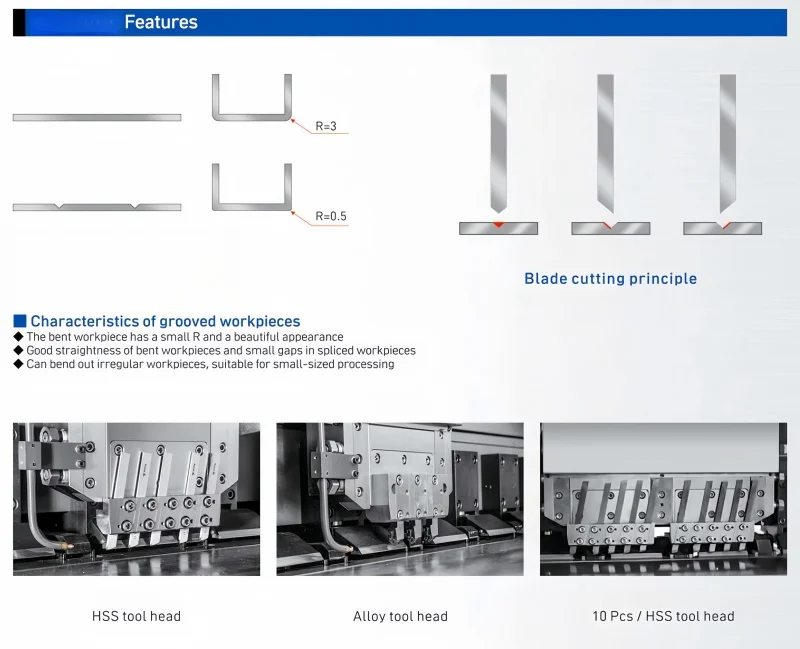

When selecting the best 6200mm V Grooving Machine for sheet metal, several factors come into play, including material compatibility, precision, control system, and performance. Key Features of the Best 6200mm V Grooving Machine: Large Capacity for Wide Panels A 6200mm V Grooving Machine should be able to handle large panels with a width of up to 6200mm, making it suitable for extensive sheet metal work such as in construction, decorative panels, and large-scale fabrications. Material Versatility The machine should be able to groove a variety of materials, including: Mild steel Stainless steel Aluminum Copper and other non-ferrous metals Ensure the machine can handle thicknesses typically ranging from 0.5mm to 8mm for most metals. CNC Control System A CNC system is essential for precise control over the groove depth, position, and pattern. The best machines come with an intuitive, user-friendly CNC interface that allows for: Easy programming of complex grooving patterns Memory storage for recurring jobs Integration with automated systems for enhanced productivity High Precision and Accuracy The machine should have high-precision linear guides and ball screws, ensuring smooth and accurate grooving. Look for machines that offer precision to within 0.01mm, especially for applications requiring clean, sharp bends. Durable and Rigid Construction The frame and body of the machine should be made from high-quality materials, such as steel welding treated for stress relief to prevent deformation over time. This ensures long-lasting accuracy and reliability, even under heavy loads. Servo Motor Drive Opt for machines that feature servo motor drives for the positioning of the workpiece and the movement of the cutting head. Servo motors offer higher efficiency, faster response times, and better precision compared to standard motors. Hydraulic and Pneumatic Clamping For secure and consistent holding of the sheet metal during the grooving process, top machines will include hydraulic or pneumatic clamping systems. This prevents movement during operation, leading to more accurate results. Safety Features The machine should come equipped with safety mechanisms such as: Emergency stop buttons Safety shields or barriers Automatic stop sensors in case of an error or obstruction These features are crucial for protecting both the machine and operators. High Efficiency Machines with automatic tool changers or rapid positioning systems will reduce downtime and increase throughput. Efficient dust and debris removal systems will also contribute to cleaner operations and longer tool life. Application-Specific Tooling The best machines will offer customizable tooling options for specific grooving needs. Look for tooling that can be swapped out easily depending on the type of groove or material being processed. Maintenance and Support Easy access for maintenance is important, with quick-change tool systems and modular parts that can be replaced without extensive downtime. The best manufacturers provide ongoing technical support, warranty services, and regular software updates. Applications of a 6200mm V Grooving Machine: Architectural panels Interior and exterior decorations Sheet metal furniture Automotive and aerospace applications Custom metalwork

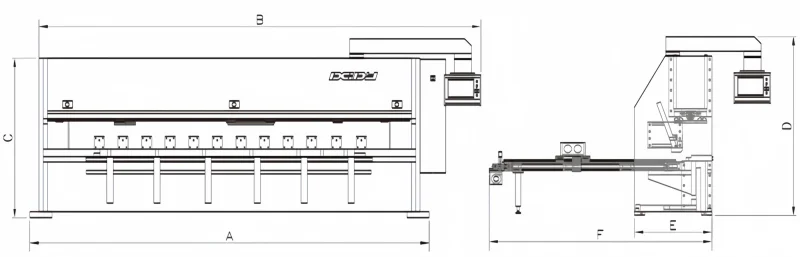

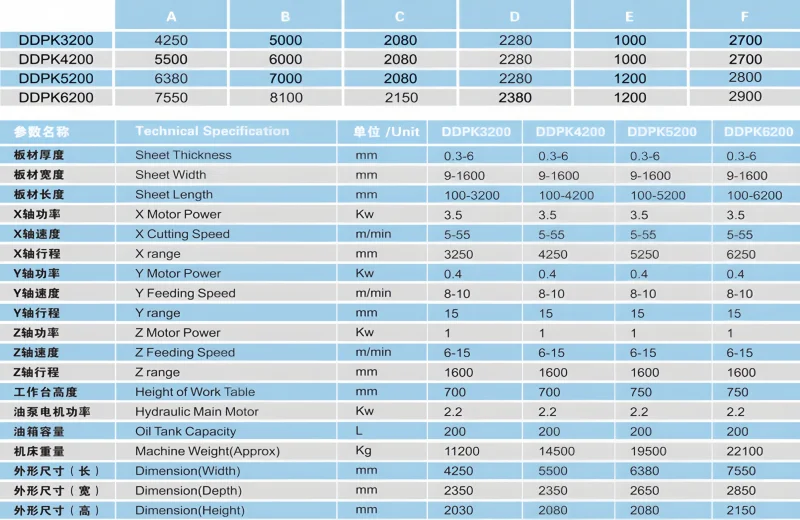

PRODUCT SPECIFICATIONS

|

No |

Item |

Unit |

LC-DPCK3200 |

LC-DPCK4200 |

LC-DPCK5200 |

LC-DPCK6200 |

|

1 |

Plate thickness |

mm |

0.3-6 |

0.3-6 |

0.3-6 |

0.3-6 |

|

2 |

Board width |

mm |

7-1600 |

7-1600 |

7-1600 |

7-1600 |

|

3 |

Processing length |

mm |

3200 |

4200 |

5200 |

6200 |

|

4 |

Workbench height |

mm |

700 |

700 |

700 |

700 |

|

5 |

Oil pump power |

KW |

2.2 |

2.2 |

2.2 |

2.2 |

|

6 |

Fuel tank capacity |

mm |

200 |

200 |

280 |

280 |

|

7 |

Feeding speed |

mm/s |

200 |

200 |

200 |

200 |

|

8 |

Planer speed |

mm/s |

100-900 |

100-900 |

100-900 |

100-900 |

|

9 |

Cutting speed |

mm/s |

280 |

280 |

280 |

280 |

|

10 |

Size |

mm |

5.2*2.3*2.1 |

6*2.3*2.1 |

7.2*2.3*2.15 |

8.1*2.3*2.18 |

|

11 |

Weight |

KG |

11200 |

14500 |

19500 |

22500 |

PRODUCT CONFIGURATION