PLC Controlled Automatic Four-Station Automatic Hydraulic

Four-Station Automatic Hydraulic Riveting Machine M625-4E for riveting angle steel flange and galvanized sheet metal

Four-Station Automatic Hydraulic Riveting Machine M625-4E A: High Efficiency and Energy Saving During operation, the high-pressure pump controls speed while the low-pressure pump assists in increasing pressure. When there is low flow demand, only the small pump operates independently, ensuring efficient system operation. Adjustable speed prevents excessive oil temperature, maintaining the hydraulic system's stability and efficiency. ECO energy-saving mode automatically shuts off the equipment motor 10 minutes after no riveting operations, promoting energy conservation. B: Self-developed Upper and Lower Mold Module Design The machine adopts a vacuum adsorption method for the upper mold, allowing automatic mold change, significantly improving production efficiency. The upper mold storage uses closed-loop stepper motors and screw modules for quick, precise movement, and positioning. The unique design of the upper mold head ensures high compatibility and practicality, requiring only 3 types of upper mold heads to meet various production needs, greatly enhancing equipment flexibility and efficiency. The automatic lower mold changing device includes lower mold storage and retrieval mechanisms using servo motors, screws, and linear guides for fast and accurate movement, positioning at fixed mold access points. Cylinders in the lower mold storage play a crucial role in efficient ejecting or retracting of the lower mold. The retrieval mechanism swiftly delivers the lower mold to the correct position for rapid replacement. C: Four-Station Automatic Feeding System Includes four custom precision vibratory bowls, suitable for various non-standard riveting tasks. The automatic feeding system supports feeding of nuts, nut columns, and screws ranging from M2 to M5 sizes, providing riveting efficiency five times greater than manual feeding. Product Overview: Model Parameters M625-4E Four-Station Automatic Hydraulic Riveting Machine Pressure Range 3-53KN Drive System PLC control Display Screen 10-inch TGA touchscreen display Dimensions 1470mm×1050mm×2000mm C-type Throat Depth 648mm C-type Throat Height 450mm Stroke Distance 200mm Weight 1000KG Power 1.5 KW Oil Tank Capacity 60L Power Supply (Voltage) 380V 3-phase 5-wire 50HZ

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

M618-NC (Single Pump) Easy Operation Press Fastener Hydraulic Insertion Machine

|

No |

Drive System |

PLC |

||

|

1 |

Force |

3-53KN |

||

|

2 |

Throat Depth |

648mm |

||

|

3 |

Throat Height |

450mm |

||

|

4 |

Cylinder stroke |

200mm |

||

|

5 |

Electric Power |

380-400V 3PHASE 50HZ |

||

|

6 |

Applicable rivet types |

Nuts: S-M3-0/1/2 , S-M4-0/1/2 , S-M5-0/1/2 , S-M6-0/1/2 , S-M8-1/2 |

||

|

7 |

Drive mode |

Hydraulic system |

||

|

8 |

Hydraulic pump motor power |

1.5kw |

||

|

9 |

Equipment size |

Length*width*height = 1100mm*950mm* 2050mm |

||

|

10 |

equipment weight |

1000kg |

||

|

11 |

Air pressure |

0.6 MPa |

||

|

12 |

Fuel tank capacity |

60L |

Hydraulic riveting machines are suitable for connecting steel sheets, stainless steel sheets, aluminum sheets, and non-metallic interlayers. Typical parts connected using a riveting machine without rivets include: Roof windows Bumpers Exhaust pipes Fuel tanks Brake covers Doors Instrument frames Engine mounts Engine covers Tailgate panels Radiators Seats Window regulators Mufflers Refrigerator doors Washing machine housings Fan housings Photocopier bases Computer cases Dental equipment casings These components span various industries from automotive to household appliances and office equipment.

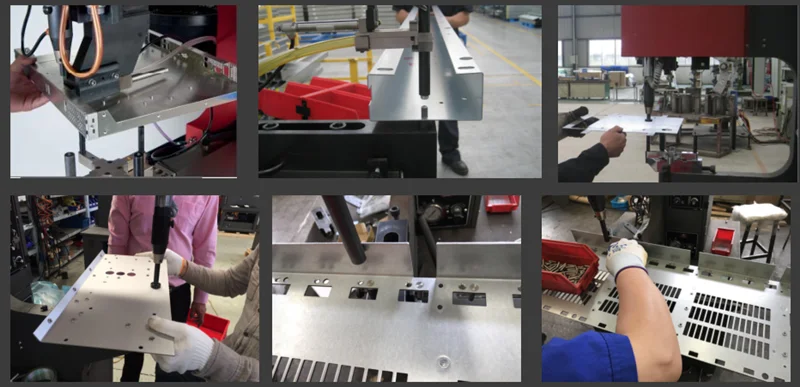

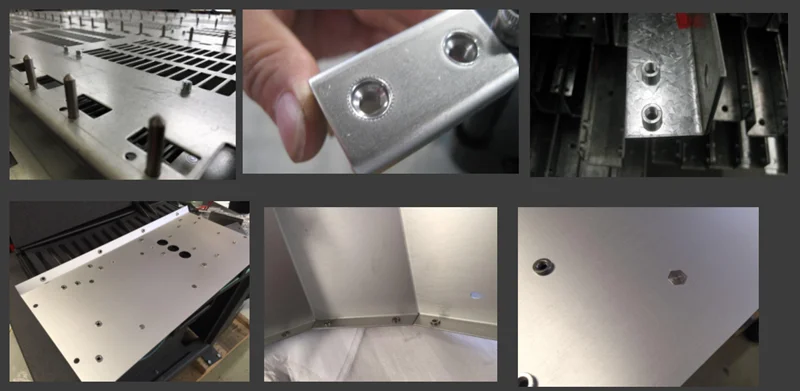

PRODUCT CONFIGURATION

Pressure riveting operating system: The system can realize CAD graphics import programming function and can realize layer hole selection, visual hole position correction function, pressure riveting process parameter self-learning function, pressure data real-time display and traceability system, and product hole position automatic detection function , Product trial processing function. Optional signal connection with robot automatic loading and unloading.

Three visual riveting working modes : ① Three-point MARK working mode : for products with small deformation and incoming hole position accuracy consistent with the drawing ; ② Shoot, press, and work mode : for large deformation and incoming hole positions Products whose accuracy cannot be guaranteed ; ③Visual measurement automatic compensation riveting mode : For products incoming from the same blanking equipment , the actual hole position accuracy is inconsistent with the drawing ;Scope of application : In the riveting state, riveting of product sizes within 800mm*600mm ( multiple products can be placed for simultaneous riveting within the stroke range of small products) can achieve up to 4 different types of rivet riveting; the maximum bending avoidance height of the product 60mm ; the distance from the riveting center hole to the bending edge is ≥ 10mm ; the maximum allowable height difference on the same plane is 30mm . Product change: Select the automatic tools and workpiece tooling plates corresponding to the type of pressure rivets according to product needs, and import CAD graphics for programming .Graphic input programming; visual correction; eliminating mistakes and missing rivets .the machine is user-friendly, the human-machine interface is simple and easy to operate, the pressure, position and speed can be set arbitrarily on the computer screen, and the stroke is adjustable .It adopts all-electric servo pressure riveting, real-time feedback from the pressure sensor, closed-loop pressure control, and high pressure accuracy, which can meet the process requirements of different materials.

Programmable , the program can set the 4- station pressure, holding time, and number of fasteners.

uBuilt-in counter , can count pieces, export online ( U disk copy) alarm information, riveting time, riveting force, production

data, etc.uThe program software can store up to 1 million riveting programs .

greatly improves production efficiency, enables continuous and stable riveting operations, reduces manual intervention, increasesproduction speed, ensures product quality, and meets diversified production needs .Easy to learn and use, flexible production, you can learn programming in 10 minutes and complete product changeover in half an hour .