Precision Levelers for Laser Cut and Stamped Sheet Metal Parts

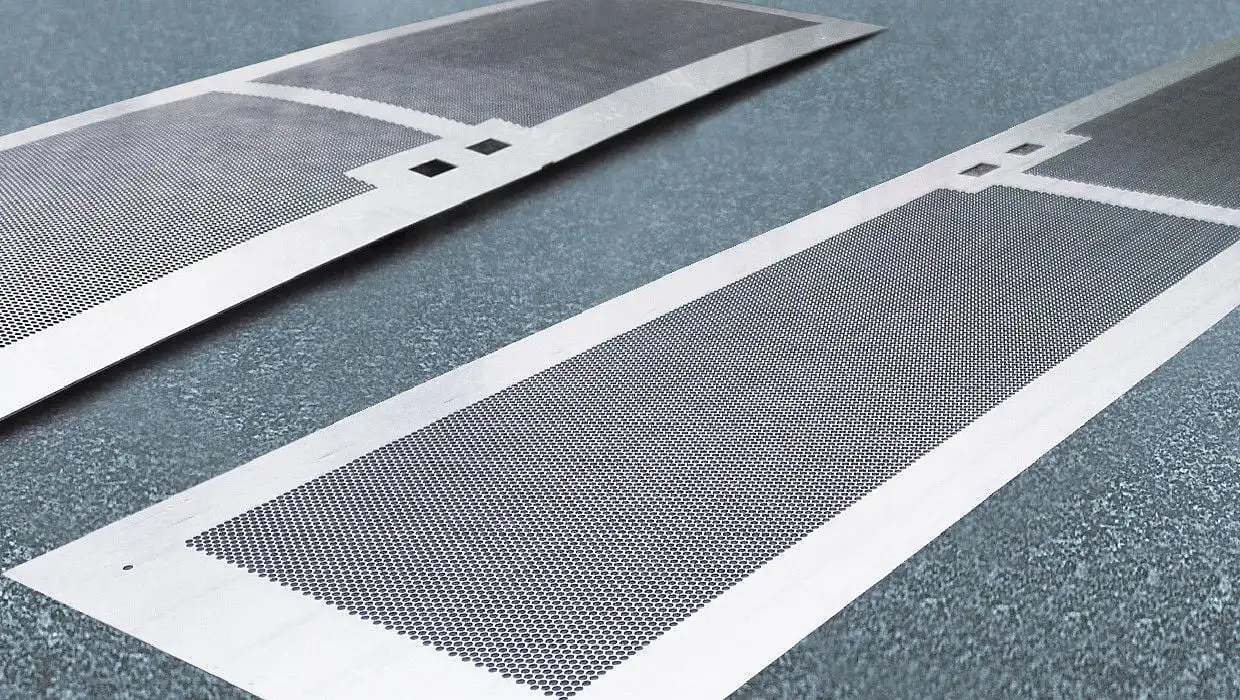

Precision Levelers Leveling Machine for 6mm Perforated Metal Sheets and architecture perforated metal sheet

Leveling Machine for Perforated Metal Sheets (6mm Perforated & Architectural Metal Sheets) This leveling machine is designed for perforated metal sheets and architectural perforated metal sheets, providing precise flattening of materials ranging from 1.5mm to 8mm in thickness. The machine is highly versatile, catering to both small and large sheet sizes, making it ideal for use in industries such as architecture, construction, automotive, and manufacturing. Key Technical Specifications: Processing Thickness: 1.5mm to 8mm (suitable for a wide range of sheet metal thicknesses, from thin architectural panels to thicker industrial perforated sheets). Width: 400mm to 3800mm (offers flexibility in handling both small and large sheet sizes). Capable of leveling various sheet widths, making it suitable for both standard and custom-sized perforated sheets. Roll Diameter: 80mm (this diameter is ideal for handling sheets of varying thickness while ensuring uniform leveling across the entire sheet). Number of Rolls: 19 Rolls in total: Upper Rolls: 9 Lower Rolls: 10 The configuration of the rolls ensures a balanced pressure distribution across the perforated metal sheet, enabling efficient leveling. Roll Gap Adjustment: Four-Point Automatic Adjustment Driven by Servo Motors: This advanced adjustment system ensures precise control over the gap between the rollers, allowing the machine to handle different sheet thicknesses with ease and providing high accuracy in leveling. The four-point system ensures even pressure across the entire sheet, which is particularly important for perforated materials that may warp or bend due to the holes in the sheet.

FEATURES AT A GLANCE

sheet metal leveling machine

sheet metal forming machine

metal sheet machine

sheet leveling machine

sheet metal leveling

sheet metal leveling

sheet metal leveling

PRODUCT SPECIFICATIONS

|

Model |

DPG-60CNC |

DPG-80CNC |

DPG-100CNC |

DPG-120CNC |

|

Width |

400-2200mm |

400-3800mm |

400-3800mm |

400-3800mm |

|

Roll diameter |

60MM |

80MM |

100MM |

120MM |

|

Rated thickness |

1-6mm |

1.5-8mm |

3-12mm |

4-16mm |

|

Maximum thickness |

6mm |

8mm |

12mm |

16mm |

|

Number of rolls |

19(UPPER 9Pcs,Lower 10Pcs) |

19(UPPER 9Pcs,Lower 10Pcs) |

19(UPPER 9Pcs,Lower 10Pcs) |

19(UPPER 9Pcs,Lower 10Pcs) |

|

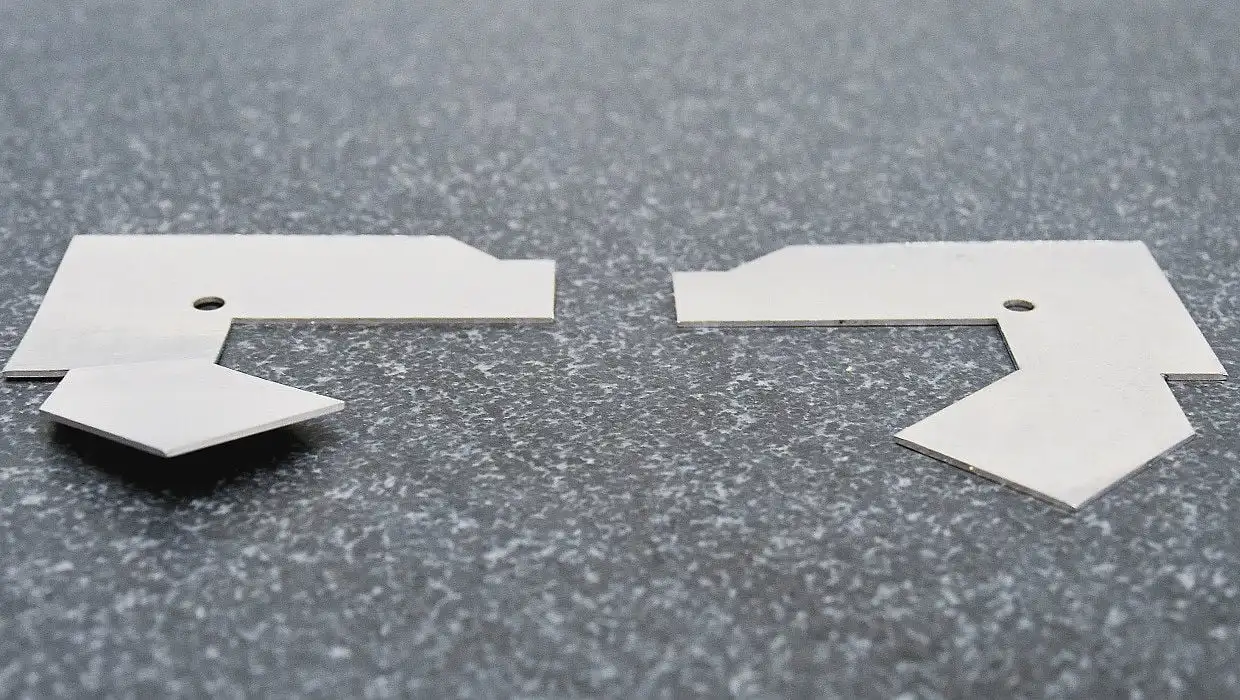

Shortest part |

15X120MM |

40X150MM |

60X180MM |

60X200MM |

|

Leveling speed |

0-12m/min |

0-12m/min |

0-12m/min |

0-12m/min |

|

Leveling roller gap adjust method |

Four points auto,Adjust driven by servo motors |

|||

|

Voltage |

3-phase 380V |

3-phase 380V |

3-phase 380V |

3-phase 380V |

Features and Benefits: Precise Leveling: The automatic four-point gap adjustment driven by servo motors ensures high precision in leveling. This allows for the accurate flattening of perforated metal sheets without causing damage to the surface or altering the perforations. Versatility: Capable of processing a wide range of thicknesses from 1.5mm to 8mm, making the machine suitable for different types of perforated and architectural metal sheets used in various industries, including construction, architecture, automotive, and manufacturing. Efficient and Consistent: The 80mm roll diameter and 19 rolls provide even pressure across the entire sheet, ensuring that perforated metal sheets are leveled uniformly, regardless of the number or size of perforations. This ensures that architectural metal sheets used in facades, screens, and other applications maintain their quality and flatness after the leveling process. Advanced Servo Motor Control: Servo motors provide highly responsive and precise control over the four-point roll gap adjustment, which is critical when dealing with materials of varying thickness. The automatic adjustment process helps improve the overall efficiency of the leveling operation and reduces the need for manual intervention. Wide Application Range: Ideal for processing perforated metal sheets commonly used in architectural panels, decorative screens, and filter elements. The machine can handle both small-scale and large-scale production, making it highly flexible for different manufacturing environments. Suitable for various applications where flatness is critical, such as in metal facades, grilles, louvers, and other perforated materials. Advantages: High Precision: The servo-driven four-point adjustment provides precise control over the leveling process, which is crucial for maintaining the integrity of the perforations and the overall flatness of the sheet. Durability: The machine is designed to handle sheets with perforations without causing any additional damage. It is constructed with durable materials and engineering to ensure long-term reliability in heavy-duty industrial environments. Ease of Operation: The automatic adjustment system minimizes the need for manual adjustments, reducing operator involvement and increasing efficiency. Cost-Effective: By increasing production efficiency and minimizing waste, this leveling machine can help reduce overall operational costs in sheet metal processing, making it a valuable investment for manufacturers working with perforated and architectural sheets. Applications: Architectural Perforated Metal Sheets: Used in building facades, cladding, screening, and decorative panels. The machine ensures that the metal sheets are perfectly flat, maintaining a high-quality finish. Perforated Sheets for Industrial Applications: The leveling machine is ideal for perforated metal sheets used in filters, grilles, and ventilation systems, where precise leveling is critical for functionality and appearance. Automotive and Aerospace: Leveling perforated metal sheets used in the automotive and aerospace industries, where precision and surface quality are important for structural components and design aesthetics. Construction Industry: Used for preparing perforated sheets for staircases, railings, mesh panels, and other construction components.