600mm parts deburring machines suitable for small parts

600mm parts deburring machines suitable for small parts deburring edge rounding and finishing after laser cutting and punching

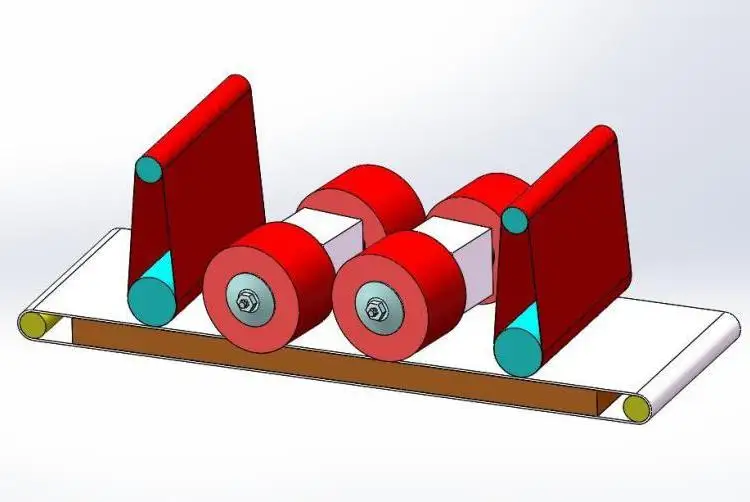

1.1. Deburring Function The machine is equipped with an abrasive belt system. The abrasive belt, driven by a grinding roller, rotates at high speed to perform wire-drawing and deburring on the workpiece surface. 1.2. Chamfering and Edge Rounding Function The machine features a set of roller brush structures. 4-8 abrasive roller brushes rotate at high speed around their axes, driven by a central spindle, to smooth and round the edges of the workpiece, achieving a chamfered and rounded effect. 1.3. Dust Collection Function The machine is equipped with a wet vacuum dust collector. Dust generated during operation is effectively removed by the dust collector, ensuring a clean and safe working environment. Principle Overview 2.1. Working and Grinding Structure The grinding mechanism adopts a wide abrasive belt system. The abrasive belt is arranged longitudinally and features professional lift and oscillation mechanisms for high-precision wire-drawing on the workpiece surface. A polishing wheel can be added for fine polishing and wire-drawing tasks. The polishing wheel is adjustable in both vertical and horizontal directions. 2.2. Workpiece Fixation and Conveying Mechanism Option A: Uses pressure rollers for fixation and a conveyor belt for feeding. The conveyor speed is adjustable via frequency conversion. Option B: Uses a permanent magnetic worktable for adsorption of ferrous materials, along with a conveyor belt for feeding. The conveyor speed is also adjustable via frequency conversion.

600mm parts deburring machines For a 600mm parts deburring machine with magnetic adsorption for small parts, here are some options and details to consider: Recommended Features for a Magnetic Adsorption 600mm Machine Effective Working Width: 600mm to accommodate a variety of small parts while maintaining compactness. Minimum Part Size: Typically supports parts as small as 50x50mm. Key Functions: Deburring: Removes sharp edges and burrs effectively. Edge Rounding: Achieves an edge radius of R0.1-0.5mm for smooth contours. Surface Finishing: Provides uniform surface treatment, including polishing. Magnetic Adsorption: A permanent magnetic table ensures stable fixation of ferrous parts during processing. Suitable for handling intricate or small components that require precise control. Dust Management: Wet or Dry Dust Collection: Ensures a clean working environment and efficient removal of processing debris. Example Machine Specifications Model: R-WX600M (Magnetic Adsorption) Working Width: 600mm Processing Thickness: 0.5-60mm Minimum Part Size: 50x50mm Deburring Tools: Abrasive Belt System for large burrs Roller Brush System for fine deburring and edge rounding Magnetic Table: High-strength permanent magnetic table for stable part fixation Ideal for thin or small ferrous components Speed Control: Conveyor Speed: 0.5-6m/min (frequency adjustable) Roller Brush Speed: 8-20r/s Power: Main Motor: 11kW Vacuum Motor for Dust Collection: 7.5kW Advantages of Magnetic Adsorption Precision Processing: Ensures small parts remain fixed during high-speed operation, reducing errors. Efficiency: Simultaneously deburrs, rounds edges, and finishes surfaces in one pass. Versatility: Processes ferrous materials like mild steel, stainless steel, and other magnetic metals. Cost Savings: Reduces manual labor with automated part fixation and processing. Sourcing Options Local Chinese Manufacturers: Guangdong, Jiangsu, and Zhejiang are key regions for metalworking machinery production. Brands like Hangzhou Xinxing, JONSEN, or Qingdao Ruirong offer competitive machines with magnetic adsorption. Online B2B Platforms: Alibaba, Global Sources, and Made-in-China list several 600mm machines with customizable magnetic adsorption options. Trade Shows: Visit the Canton Fair, China Metalworking and Forming Exhibition, or CIMT to explore options firsthand.

.png)